▲

Engineered by

What is Diamond Slicing?

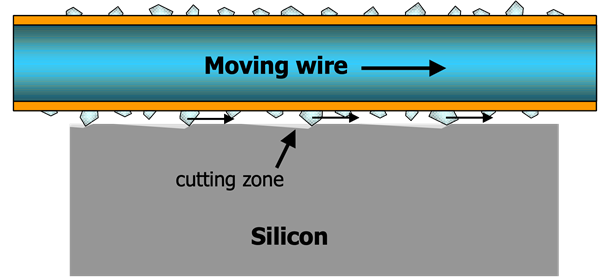

Slurry wire saw slicing vs. diamond wire saw

Slurry wire for diamond slicing

A mixture of silicon carbide and glycol is used as an abrasive that erodes rather than cuts the ingot.

Grain particles roll between wire and material.

Grain particle speed is max ½ of wire speed.

Slurry wire saw generally has:

Less damage to the substrate

Less wire deflection in inhomogeneous material.

Smoother surface

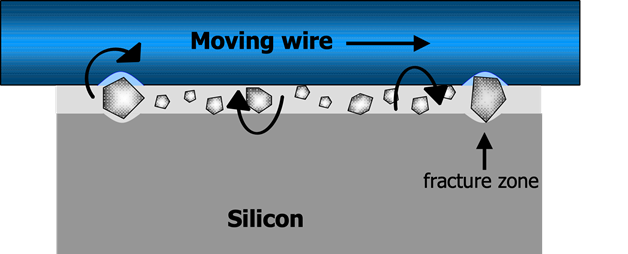

Diamond wire slicing

Diamonds are applied to the wire to create a true cutting action

Grain particles glide over the workpiece

Grain particle speed equal to wire speed

Theoretical doubling of removal rate at same wire speed compared to slurry

Diamond wire saw slicing generally has:

- Lower cost per wafer for most applications

- Significantly higher wire speed possible

- Higher removal rate

- More environmentally friendly due to water-based cutting fluids

- Cleaner machine and workpieces

- Better TTV (no wire taper)

- Less heat generation and better heat dissipation